CNC Router 1325 in Villupuram | Himalaya Technologies

CNC Router 1325 in Villupuram – Himalaya Technologies is creating a profitable strategy to import CNC Router 1325 in Villupuram.

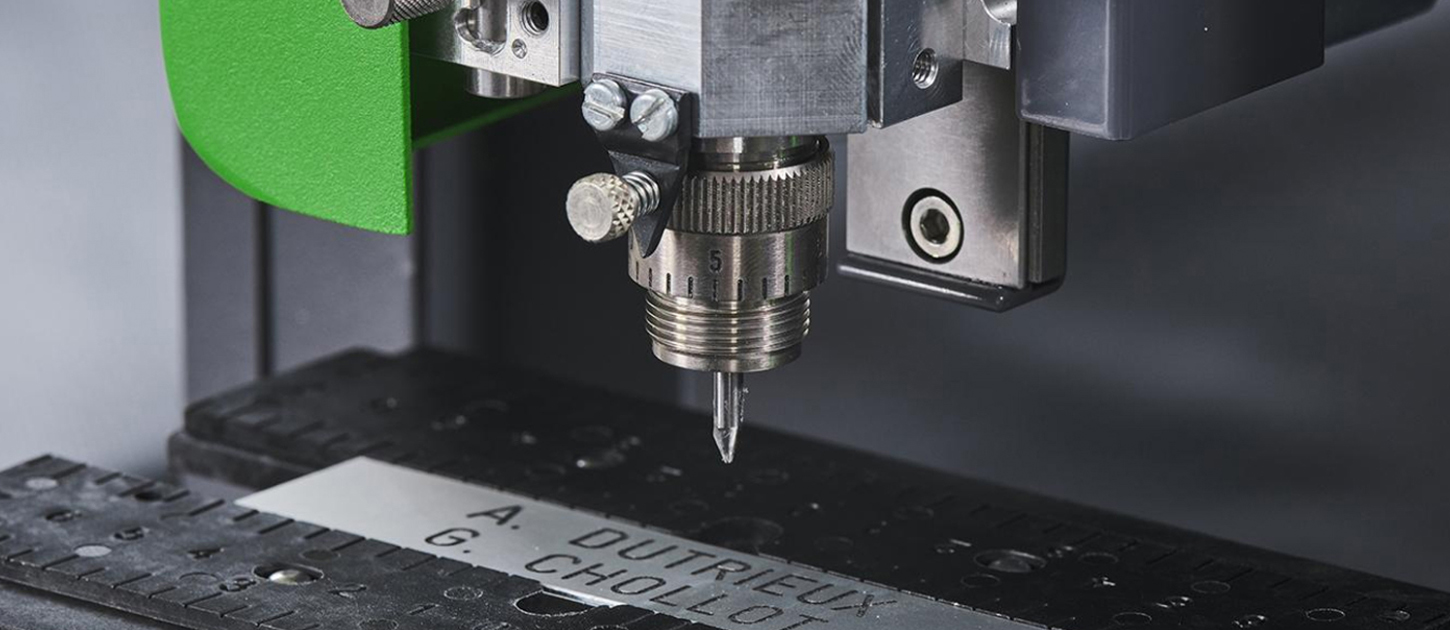

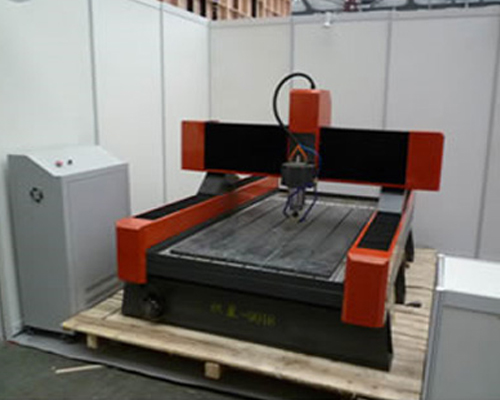

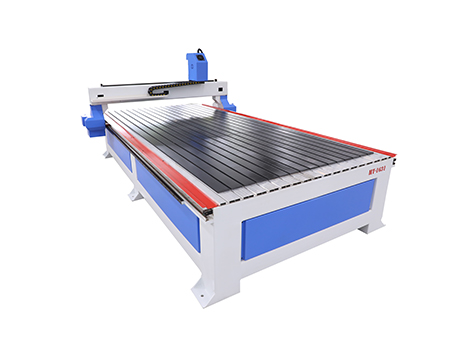

CNC Router 1325 In Villupuram – “Himalaya Technologies” We offer a range of new CNC Router 1325 machinery and associated services. The company is continually investing in modern techniques and equipment. From the latest in spindle dynamic balancing equipment, condition monitoring and thermal imaging, to complete service management software and remote machine diagnostics. CNC Router 1325 Support Team is made up of 9 skilled engineers plus admin support staff. Our engineers have experience working for major CNC Router 1325 machinery manufacturers. The company believes in staff development and training supported by local Universities and Technical Colleges.

Our engineers all have broad based skills to cater for all our customers’ requirements. To supplement this each engineer has an area of expertise, be it Service, Applications and Programming, Spindle rebuild or CNC Router 1325 design and PLC.

Our engineers are backed up by office staff with extensive knowledge of CNC Router 1325 machinery, if an engineer requires urgent parts or information it is readily available with a phone call. Give us a call! We’re here for you. 8220048337.

So without any second thought, browse our website to place your order. Drop your requirement via the enquiry form on the website or call the given number now. We are happy to help you in all possible ways.